FAQ

Lubricant, Oil and Grease

Marine lubricants are widely used in the shipping industry to protect and improve the efficiency of engines and equipment. They are specially designed to allow optimum performance in operations, such as extending engine life and protecting components at high temperatures, improving machine performance and reliability, enhancing protection against mechanical wear and reducing cold corrosion.

Lubricant controls friction and wear by introducing a film that reduces friction between moving contact surfaces. The main functions of a lubricant are:

- Reduce friction

- Prevent wear

- Protect the equipment from corrosion

- Control temperature by dissipating heat

- Control contamination to a filter

- Transmit power Provide a fluid seal

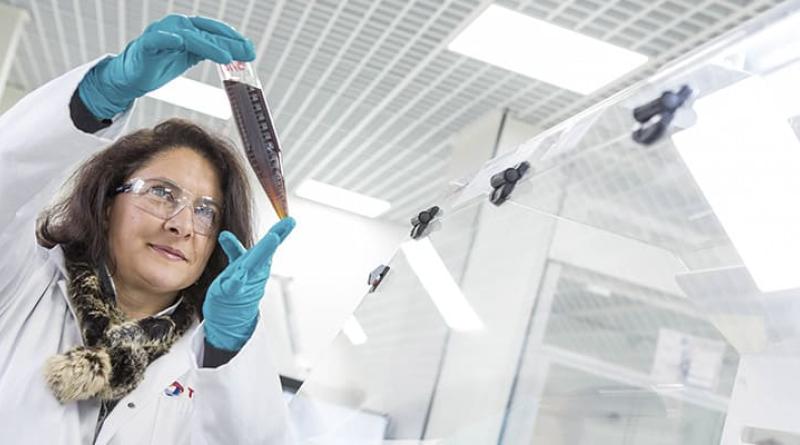

The most common forms are Oil and Grease. The oils can be synthetic, vegetable (so-called Environmentally Acceptable Lubricants - EALs) or mineral-based, as well as a combination thereof.

The application determines which oil, commonly called base oil, should be used. Under extreme conditions, synthetic oils can be beneficial. When the environment is of concern, EALs can be used.

Lubricants contain additives that enhance, add or remove the properties of the base oil. The amount of additives depends on the properties and the application for which the oil will be used.

A dispersant can be added to the engine oil.

In environments subject to extreme temperatures, from cold to hot, a viscosity index (VI) improver can be added. These additives are long organic molecules that remain clustered in cold weather and disintegrate in warmer environments. This process modifies the viscosity of the oil and allows it to flow better in cold weather while maintaining its properties at high temperatures.