Achieving the right level of two-stroke engine cylinder lubrication offers multiple benefits for vessel operators. For not only can you enjoy LOFR, OPEX control savings and increased safety margins, but you will also help prevent costly engine damage.

This is however easier said than done. Rising to the challenge requires an understanding of the multiple operating parameters of the engine, combined with smart engine monitoring and drain oil analysis and interpretation - something that can only be achieved with the support of a lubricant specialist. For not only are modern engines particularly sensitive to corrosion and corrosive wear, but the introduction of VLSFO fuels through IMO2020 further increases the risk of engine deposit build up. And with both under and over lubrication able to cause potentially expensive damage, the argument for getting the LOFR balance right makes both practical and economic sense.

At Total Lubmarine we have developed a range of tailored solutions designed to help deliver multiple benefits including:

- A high Performance, proven lubricant range including TALUSIA UNIVERSAL

- Drain Oil Analysis Services

- Worldwide DIAGOMAR PLUS Laboratories

- Global team of Marine Lubricant Engineers (MLE)

All OEM guidelines recommend careful engine monitoring and our sophisticated intelligence-led approach allows for the most prudent management of two stroke marine engines.

Key Steps to LOFR Optimization

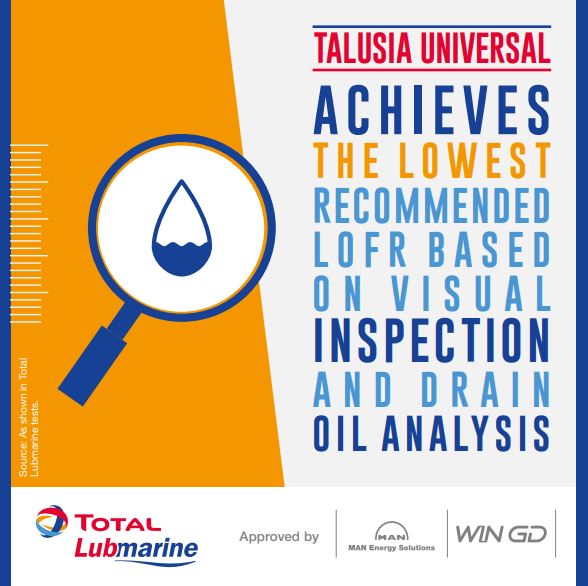

Step 1 - The Lubricant Solution - TALUSIA UNIVERSAL

TALUSIA UNIVERSAL is a fully OEM approved mid-range cylinder oil with a unique chemistry and proven with over 125,000,000 successful operating hours. It is proven to provide additional safety margins compared to BN40 CLO, achieving the lowest recommended LOFR when based on visual inspection and drain oil analysis. Thanks to its formulation (BN57 and innovative chemistry), TALUSIA UNIVERSAL is perfectly balanced to help prevent calcium carbonate deposit buildup compared to higher BN lubricants. Its additional surfactant molecules provide effortless reassurance and confidence in engine cleanliness, helping extend the operational efficiency of ship engines, saving vessel owners and engineers, both time and money in the long term.

TALUSIA UNIVERSAL is proven to handle the engine cleanliness demands of all technologies operating with low Sulfur fuels in all conditions and can be used with the widest range of 2020 compliant fuels.

Step 2 - Drain Oil Analysis Services

Our Drain Oil Analysis Programme is simple and reliable, helping optimize operations through lubricant consumption and component wear analysis. There are four drain analysis programmes to choose from.

- Standard - Provides a snapshot from the last four analysis of the engine condition focusing on OEM conformity in regards of iron and BN levels.

- Advanced – Advanced offers a more detailed analysis of the engine condition. Carried out over a longer time period, Advanced provides a comprehensive engine analysis report, including system oil contamination.

- Optimized: For optimized Lubricant consumption and maximum engine health, Optimize is a complete service delivered over a mid to long-term period including specific LOFR optimization advice from Total’s Lubmarine experts.

Testing of the drain oil samples includes residual BN, kinematic viscosity, insolubles, water content, PQ index, oxidation, iron and other metal content.

Step 3 - Tapping into Our Worldwide DIAGOMAR PLUS Laboratories

With 5 global labs, located at Ertvelde, Singapore, Shanghai, Chicago and Panama City our DIAGOMAR PLUS Laboratories offer a range of analysis services including - Engine Oil, Non-engine Oil, Drain Oil, Thermal Oil, Stern tube Oil, and EAL (Environmentally Acceptable Lubricant).

The combination of technical services, expert lubricant knowledge and specialist insight offered by our Lab network enables ship operators and crews to decide the best courses of action specific to their vessel. This is supported by the dedicated marine lubricant technical team at Total Lubmarine who can assist and advise whenever required.

Step 4 - Marine Lubricant Engineers

Our highly experienced Marine Lubricant Engineers are on hand at worldwide locations to assist with any lubrication issues vessel operators might experience and can provide a range of specialist support including:

- Ship engine inspections and trouble-shooting

- Lubrication survey and technical investigations

- Shipyard and switchover support

- Vessel machinery assessment and long-term follow-up

Conclusion

There is no single solution to achieving the benefits that LOFR optimization can deliver. It takes a multi-layered approach, utilizing the technical knowledge and infrastructure of a specialist lubricant manufacturer like Total Lubmarine.

Contact us to find the how we can support your fleet.