OEM guidelines recommend careful engine monitoring and a sophisticated intelligence-led approach allowing for the most efficient management of two stroke marine engines.

Using the right lubricant in the right amount to deliver optimum performance is just one piece in the puzzle.

Rising to the challenge requires an understanding of the multiple operating parameters of the engine, combined with smart engine monitoring and drain oil analysis and interpretation - something that can only be achieved with the support of a lubricant specialist in order to ensure an effective engine cleanliness.

3 Key Steps to LOFR* Optimization in the Post IMO2020 Landscape

Step 1 – A Proven Lubricant Solution

Talusia Universal is a fully OEM approved cylinder oil with a patented chemistry, proven with over 125,000,000 successful operating hours.

Tests show that Talusia Universal performs better than conventional BN 40 in cleaning ability (detergency) and provides higher residual BN, and therefore safety margin, enabling you to optimize the feed rate and maintain the iron content into the limits determined by the OEM’s during long-term operation.

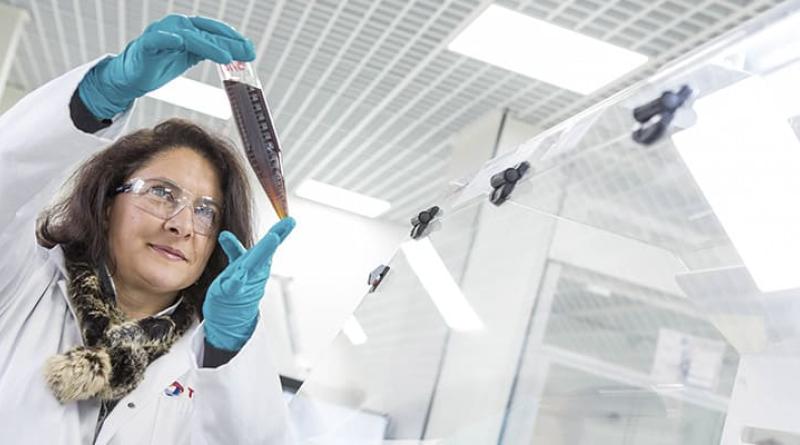

Step 2 – Implement a Robust Analysis Programme

Implementing an effective Drain Oil Analysis Programme is simple, reliable and a proven way of helping optimize operations through lubricant consumption and component wear analysis.

Drain Oil analysis programmes can offer differing levels of insight ranging from regular services providing a snapshot, focusing on OEM conformity in regard to iron and residual BN levels, through to more advanced programmes delivering comprehensive engine analysis reporting. These advanced progammes provide insights on system oil contamination and finally optimum analysis services looking at detailed mid-to-long term performance measurements including specific LOFR optimization advice and insight.

Step 3 – Marine Expertise – The Human Element

The third layer in achieving optimum engine performance including its cleanliness profile is to enlist the support of highly experienced engineers to assist with lubrication optimization and any lubrication issues vessel operators might be experiencing.

This can include:

- Ship engine inspections and trouble-shooting

- Lubrication survey and technical investigations

- Shipyard and switchover support

- Vessel machinery assessment and long-term follow up

This third step enables supporting decisions to be made on the best courses of action specific to a vessel.

Conclusion

By carefully and regularly monitoring lubricant and vessel machinery condition, ship owners together with their oil supplier can proactively detect and react to any abnormalities and contamination issues through a range of tailored solutions designed to help deliver multiple benefits.

To find out more about the benefits of a multi-layered approach to achieving engine cleanliness and optimizing your Lube Oil Feed Rate (LOFR) download our white paper – Adapting to Life in The Post IMO2020 Landscape.

*LOFR (Lube Oil Feed Rate)