This summer sees the transformation of Total’s La Mède refinery in France into a world-class biorefinery, capable of producing 500,000 tons of hydrotreated vegetable oil (HVO) type biofuels to meet growing demand. The move is part of Total’s drive to be a responsible energy major. Total’s low-carbon businesses encompass downstream gas, renewable energies, energy storage and energy efficiency as well as clean fuels and carbon capture, utilization and storage techniques.

However, it is not just about delivering renewable energy, but also developing sustainable plastics. In the bioplastics market, Total is focusing particularly on polylactic acid (PLA), a fully bio-based and biodegradable polymer with a carbon footprint one third that of conventional polymers. PLA is currently used mainly in food packaging and textiles as well as in the medical, electronic and automotive industries, and is one of the first renewable polymers able to compete with existing polymers in terms of performance.

In March 2017, Total joined forces with Corbion to create the Total Corbion PLA joint venture, which will produce and market PLA-based bioplastics. Our ambition is to become the world’s second largest supplier of PLA. A world-class PLA plant with a capacity of 75,000 metric tons per year is presently under construction in Thailand, with production expected to begin in the second-half of 2018.

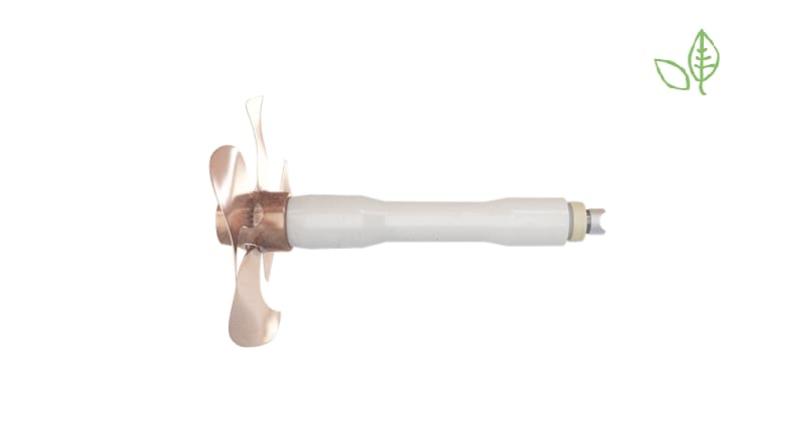

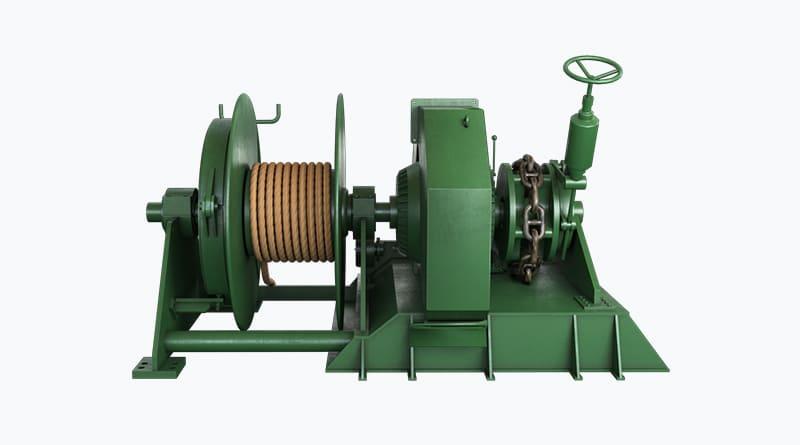

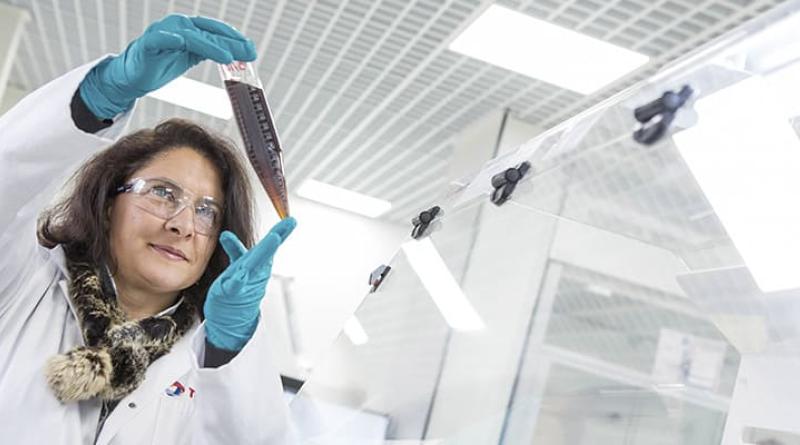

Total Lubmarine is playing its part in the sustainability drive by producing and developing a range of bio lubricants. BIO lubricants by Total are biodegradable, minimally toxic and non-bio-accumulative, in addition to being made from sustainably sourced materials. Total Lubmarine offers a complete range of synthetic ester environmentally acceptable lubricants (EALs) for use with all marine oil-to-sea equipment interfaces. With decades of expertise developing oils, fluids and greases for the marine industry, Total Lubmarine offers a full complement of products for every application, and for every type of vessel. The innovative Total R&D labs are constantly improving the product range, now including environmentally sound options to help ship operators comply with the most environmentally stringent regulations.

The family of BIO lubricants (EALs) includes:

- BIOHYDRAN (hydraulic oils)

- CARTER BIO (gear oils)

- BIONEPTAN (stern tube oils)

The BIONEPTAN range of lubricants is particularly recommended by manufacturers for the lubrication of sliding rolling bearings within stern tubes.

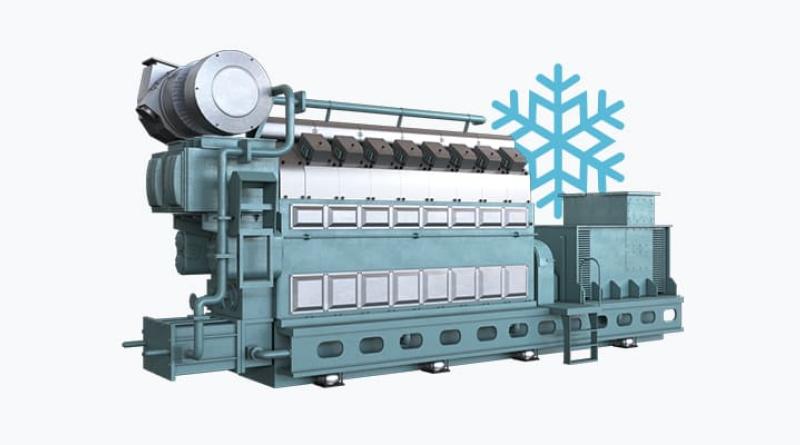

Offering outstanding viscosimetric performances, the lubricants perform in a wide range of operating temperatures, including especially low temperatures, and have excellent anti-wear and anti-corrosion properties.

BIONEPTAN products have been in use since 2013 and are currently used on over 1500 vessels. Total has received good feedback from all users.

In April 2018 we announced the introduction of a new grease product: BIO OG PLUS, an innovative addition, suitable for open gears and chains, to an already comprehensive EAL range.

More information at – https://www.totallubmarine.com/products-category/marine-bio-oils-and-greases-eal