It was a busy SMM show in Hamburg this September for Total Lubmarine. The show, one of the biggest in the maritime calendar, draws tens of thousands of visitors from across the shipping industry to meet ship service and equipment suppliers. We were delighted to see so many old friends and new faces at our stand.

The event saw the launch of Total Lubmarine’s latest product, Talusia Optima, a new cylinder lube oil compatible with high sulphur heavy fuel oils and ultra-low sulphur distillate fuels. There was great interest in the product from customers and the maritime press who wanted to examine in detail the performance of this breakthrough lube.

Total Lubmarine’s Global Marketing Manager Serge Dal Farra said that ship operators were particularly focused on Talusia Optima’s ability to simplify engine room operations, enhance engine lifetime and reduce costs.

Talusia Optima at a glance:

- Suitable for use with wide variety of fuels (0-3.5% sulphur content)

- Based on Ashfree Neutralizing Molecules technology

- Improved acid neutralization vs conventional BN 100

- Improved resistance to adhesive wear

- Higher resistance and detergency properties

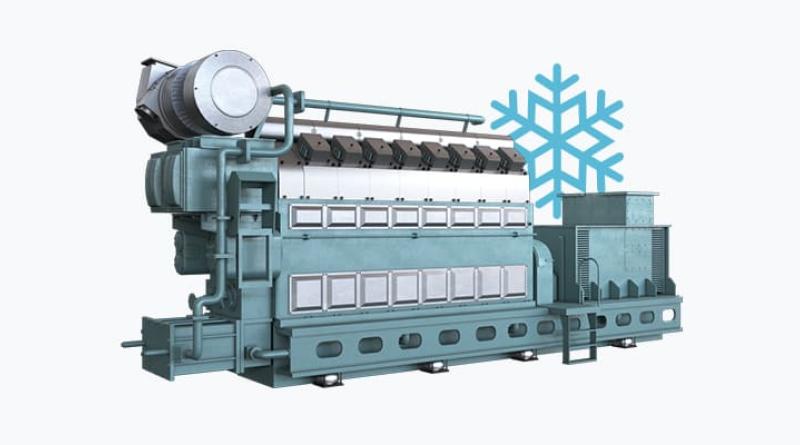

- No objection letter from WinGD for use across two-stroke engine range.

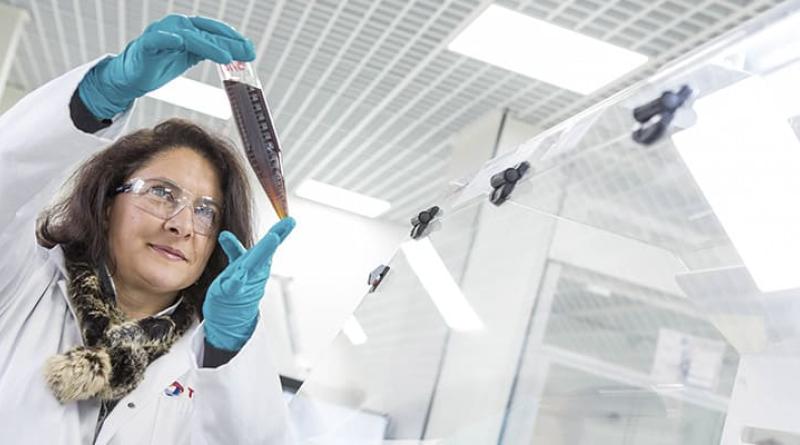

"Today is the culmination of years of work in the lab and tests at sea"

Launching the product at a special press conference in Hamburg, Total Lubmarine’s Technical Director Jean-Philippe Roman said: “Today is the culmination of years of work in the lab and tests at sea and I am delighted that Talusia Optima is now on the market and available to our customers. It will make life on-board easier for ships’ crews and greatly minimise the risks encountered during fuel changeovers. Tests conducted during sea trials have all shown that Talusia Optima’s resistance to adhesive wear is better than that of conventional BN 100 cylinder lube oils, and piston coating wear rate is improved by 30%. Indeed, the final inspection on-board one mega boxship that had used Talusia Optima for 4300 hours whilst deployed on Asia-Europe liner routes, found that its engine had perfect piston and liner cleanliness.”

He added:

“We are confident that Talusia Optima will extend the life of engines it is used in and with well monitored feed rate reduction programmes in place, offer potential savings on lube spend.”

Serge Dal Farra, Total Lubmarine’s Global Marketing Manager said:

“As the developers of the industry’s first single oil solution, Talusia Universal, we knew that demand for a single oil solution was strong. No ship operator or engineer wants added complexity and we have brought a lube that is compatible with all fuel types to market to meet our customers’ pressing need for a simple solution.

“I am delighted that as of today we can supply Talusia Optima to our customers in major ports and offer it to the wider market. Our research and technical teams have created a truly excellent product that counters and actively anticipates the current and future complexity of shipping operations.”

Talusia Optima has already successfully completed thousands of hours of sea trials on a variety of two-stroke engine powered vessels. Regular drain oil analysis during the trials showed that Talusia Optima’s residual Base Number (BN) was always higher than that of other lubricants and total iron content always lower without any hard ash deposit formation.

Talusia Optima is based on an innovative and new type of chemistry known as Ashfree Neutralizing Molecules (ANM). The unique and patented technology provides fast and effective acid neutralization without any undesired mineral deposit build up. High quality mineral components are used in combination with ANM to provide detergency and cleanliness.

WinGD has given approval for the use of Talusia Optima with its Wärtsilä RTA, RT-flex and X engines as well as in Sulzer 2-stroke engines.