As the Lubmarine Marine Lubrication Engineer (MLE) for the UK and Ireland, Christopher White is part of a team of technical specialists based around the world. He currently manages a portfolio over 250+ vessels, being the first point of contact for any technical matter to support Lubmarine’s global shipping customers.

Here, Christopher talks about his role and the varying types of support that he and his colleagues provide shipping operators and their teams – both at sea and ashore.

Can you tell us About Your Background Before Becoming a Marine Lubrication Engineer with Lubmarine?

Initially I was studying at college to be an aircraft engineer but then jumped disciplines to shipping and spent three years at Warsash Maritime Academy in Southampton, UK, studying Marine Engineering, achieving my 3rd engineer ticket as an Officer of the Watch.

I would spend time studying at college and then spend time at sea to complete the cadetship. You have to have a minimum of 12 months at sea before you could complete the course, which ultimately provides you with your ticket to go to sea.

I was sponsored through Warsash by Princess Cruises so upon qualifying I went to work for them from 2012 to 2018.

I was predominantly working with a team of engineers onboard and would be in the engine room every day. I was a watch keeper – which effectively means you manage everything – engines, generators, maintenance, strip downs, everything to do with the propulsion and associated power generators onboard a vessel including refrigeration systems, hydraulic systems, electrical systems/motors and boiler/steam systems as well as main engine overhauls and overhauls of auxiliary machinery such as pumps and compressors. This included all condition monitoring of engines, purifiers, pumps, compressors etc taking regular vibration monitoring checks, oil analysis, and also thermographic tests.

Towards the end of my time at sea that we were starting to see the implications of IMO 2020 come in. So, for example I was responsible for a project commissioning scrubber systems. It was an interesting role, which was more revolved around looking at the technical implications and changes in systems and design through to installation.

It was a big change and there was certainly an emphasis on the cruise industry to adopt those changes.

After seven years at sea and having met my partner, I wanted a change that enabled me to spend more time ashore and I saw the opportunity to join Lubmarine as a Marine Lubrication Engineer. I applied and was very glad to be offered the role.

Can you Tell Us More About Your Role as a Marine Lubrication Engineer and What Is Involved?

I am part of a worldwide team of Marine Lubrication Engineers here at Lubmarine and support the shipping companies/vessels/end users in the right choice and application of marine lubricants for the entire vessel, from main engines, auxiliary engines, steering gears, all auxiliary equipment, deck cranes, hatch covers etc.

I am also responsible for creating and maintaining the lubrication charts for all 250+ ships within my portfolio, advising which lubricants to use and offer alternative solutions if not available, alongside supervising all of the used oil analysis and monitoring, providing detailed explanation of potential causes/problems from the analysis, providing assistance to ship crews, organizing the collection of lubricants, and answering all types of technical enquiries from customers regarding their used oil analysis.

Almost all the MLEs within Lubmarine have seafaring experience from an engineering capacity which is extremely beneficial as we can use that experience to add value to our customers’ needs. They certainly like the fact that our team has seafaring experience as I think it provides them with added confidence. That background enables us to understand many of the issues from a practical perspective which is aligned to the support we offer them.

We tend to work closely with technical superintendents, chief engineers and second engineers and also deal with procurement teams who will often ask for input from us on certain oils.

What is vital is the relationships that we build with our customers and the responsiveness and fact we are on hand to support them directly, when they need us. We value the relationship we have and technical support we can offer.

A key part of our work also sees us performing ship visits – from emergency situations, customers’ requests, planned scheduled ships maintenance visits, performance monitoring, and new product change over supervision on everything from LNG tankers, FPSO (Floating Production Storage and Offloading), tugs and general cargo carriers to offshore cargo vessels.

Despite varied customers groups – the challenges are the same from an engine lubrication perspective and our role is to support our customers and add value.

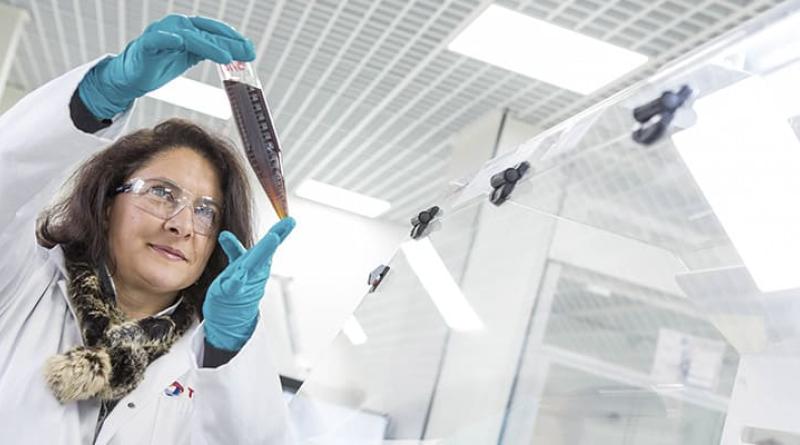

We also play a role in new product development which must go through extensive sea trials. So, we will be liaising with the R+D and wider technical teams within Lubmarine, with the shipping owner and crew and helping set up and manage the parameters of the trial, assessing development results and making any required modifications.

The Shipping Industry is on a Decarbonization Journey – Are You Having Different Types of Conversations with Customers as a Result?

Certainly the discussions around new marine fuel solutions are increasing, with Ammonia and Methanol the seeming front runners based on what customers are saying to us. It is an interesting time to be working in the shipping industry from a technical perspective with this major change to low emission and clean fuels.

But of course, whilst shipping companies are looking to the future and determining which fuel direction they will take, we are focussed on supporting their operations today through the combination of performance products such as Talusia HD 40 and increasingly using a growing range of digital tools that we are developing to support onboard monitoring and measurement processes.

Customers are increasingly aware of the importance and benefits of digital testing and monitoring systems and the data driven decisions which can make their operations more efficient which in turn can save them money.

Every customer we speak to is very excited by the digital tools we now have available. Going digital is a big change – but they see the benefits that it brings.

When Not at Work How Do You Spend Your Spare Time?

I love motor sport and golf – whether that is watching or taking part.

I also have a 10-month-old son so those hobbies have certainly gone on hold a little. But I absolutely love being a dad.

One of my other sporting passions is Newcastle United and I am a season ticket holder and go to as many home games as I can.