Having started his career in the United States Merchant Marine Academy, Michael Kane has spent the last 12 years with Lubmarine in North America, currently working as the Supply Chain Manager and Regional Customer Services Manager.

Here he shares the challenges of working in such a large continent and looks at how the last 18 months in particular have proven some of the most challenging times in his career at Lubmarine to date and how through understanding the market combined with effective planning, Lubmarine has overcome them.

Q) Can you tell us about your background and how you came to work at Lubmarine?

I graduated from the United States Merchant Marine Academy where I started my career as a project engineer in Naval Shipbuilding. After several years, I transitioned my career to sales where I worked for Michelin North America in New York City. I then went back into education to get my International MBA in a Tri-Continent programme with Temple University in Tokyo & Philadelphia campus and Ecole Nationale des Ponts et Chaussées in Paris. This created the opportunity for me to begin my career with TOTAL in 2009 as a Marine Sales Manager. In 2016, I switched to the supply side of the business to help Lubmarine become more competitive in the North American market. I currently fulfill two roles within the business here in North America – Supply Chain Manager and Regional Customer Services Manager.

Q) What do your current roles involve?

Within my Supply Chain manager role I am involved in two key functions:

- To ensure reliability with a competitive and diverse supply chain to ensure our customers get the products they need when they need them regardless of Covid, Climate Change or cyber attack (the Texas Freeze and Colonial Pipeline hack disrupted USA Supply Chains).

- To seek to reduce CO2 emissions by minimizing truck movements and utilizing rail transportation whenever possible.

A lot of my time is spent working directly with our networks of suppliers to ensure that we have the right materials in stock in tandem with the tank space to ensure our products are ready when our customers need them. We work with different blend plants to ensure we have access to enough raw materials and products in the right amount and the right locations. We need to be flexible.

Within my role as Regional Customer Services Manager I work closely with our Order Managers, Delivery Managers and Key Account Managers to ensure our customers get the information they need to enable them to get the products they need when they need them. What’s for sure is that every day is a unique challenge.The sheer size of North America is an example of that. Each state can have different regulations for different deliveries. Different tax forms, port restrictions, regulatory restrictions and delivery methods. The diversity of different regulations across the states means we need to be on the ball and understand those implications.

Q) What type of customers and sectors are you supplying Lubmarine products into?

We primarily supply international and interstate trading vessels such as tankers, bulk carriers and container ships. We are also growing our business in the cruise sector as well winning more and more business from traditional operators in the market. We are also looking at growing our inland waterway and offshore business, which is an interesting market for us to develop in.

Away from the shipping sector, a growing part of our business is supplying power plants in the Caribbean. We are well positioned out of Houston to service this market and have also been exporting flexi-bag containers (*) from Houston to the Bahamas and Dominic Republic.

In terms of the products supplied to the power sector we provide TALUSIA UNIVERSAL and also send a lot of AURELIA TI 4055 and DISOLA M4015.

Q) In addition to Lubmarine products how do you add value to customers?

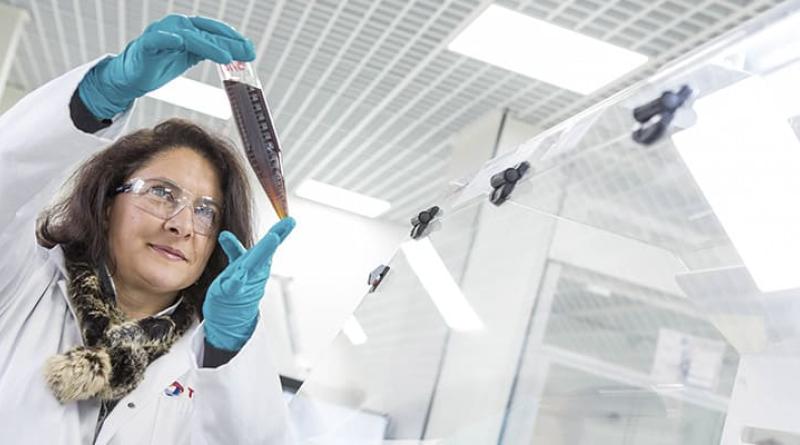

What has made us successful with our customers is the close relationship we have with them. Not only are we close to them geographically but we really work hard to understand their business and are proactive in the solutions we offer them. If something isn’t possible we will give them alternatives and work hard to provide them with flexibility to suit their needs. The range of technical services and support we offer our customers is also a valuable differentiator and something they really value. For example having the Chicago lab is an advantage for our customers and something they like.

Our approach is to be a partner with our customers, to provide consultative support and not just be an order supplier. We keep in close contact with our customers and have regular calls and meetings.

Q) What have been the biggest challenges you (and your customers) have faced over the last 15 months and how have you overcome these?

I think it’s fair to say that the last 18 months have seen us having to tackle some of the most unprecedented series of situations we have ever seen. Obviously Covid has had a major impact in terms of how we have been able to work but in tandem with that we had to deal with the impact of the Texas Freeze, which struck here in February. This was a regional freeze on a scale that we have never seen before. When it struck it shut down chemical and oil refineries and when they shut down it can take weeks and months to get them back up to speed. Such was the severity of the freeze that the additive refineries and base oil refineries were dealing with broken pipes and valves, in addition to the fact that people just could not get to work. Texas has gotten cold before but not like this and not for so long. The impact was massive in the market (and we are still seeing that impact even now) but thanks to our approach of having a range of base oil and additives suppliers across North America we were better positioned to weather the crisis than our competitors.

We were able to source base oil from both the East and West coast and had good levels of additives reserves to see us through. Due to our diversified position of having more base oil, additive and blending plants within our portfolio, we have been able to minimize disruption for our customers and position ourselves ahead of the market by being able to offer higher volumes.

Q) When you are not in work mode – what do you like to do in your spare time?

I like my sports and enjoy coaching my 6-year-old boy’s Little League Baseball Team in the Spring and I am also learning to play golf.

(*) Flexi-bags are essentially large rubber bags within a shipping container. Think of a 20ft box of wine. This enables us to send 20 tonnes of lubricant to the Islands on a vessel in a highly efficient way.