Everyday choices made by people, business and government hold the key to all our efforts to reduce emissions globally and find more sustainable clean energy solutions. Today is Zero Emissions Day which is designed to raise awareness about the need for cleaner air by creating less emissions and to engage everyone towards more climate-friendly choices. The international shipping industry, as with other industry sectors, is under more pressure than ever before to reduce it Greenhouse gas (GHG) emissions, with The International Maritime Organization (IMO) announcing its ambition to reduce these emissions from shipping by at least 50% by 2050 compared with 2008 levels.

Diesel engines used as the main power supply of marine vessels produce a range of emissions, including carbon monoxide (CO), carbon dioxide (CO2), nitrogen oxides (NOx), sulfur oxides (SOx), hydrocarbons (HC), and particulate matter (PM). The most relevant limits are those related to the percentage of sulfur content (SOx) in marine fuels and emissions of nitrogen oxides (NOx) from engines.

To meet IMO requirements, ships must use fuel oil, which is inherently low enough in sulfur, or install an appropriate exhaust gas cleaning system, also known as “scrubbers”, or have engines which use alternative fuels, with low or zero sulfur, for example liquefied natural gas (LNG) or biofuels. Since 1 January 2020, ships have been required to use fuel oil containing a maximum of 0.50 per cent m/m sulfur.

The maritime sector is beginning to make some significant steps to reduce air pollution. To reduce SOx emission, limits have been set on the sulfur content of the fuels. Emission Control Areas (ECAs) with stricter limits were established to minimize airborne emissions from ships. The resulting reduction in sulfur oxide (SOx) emissions from ships is having major health and environmental benefits for the world, particularly for populations living close to ports and coasts. The SOx emission limits apply to the existing fleet and NOx emission limits were set for new build ships.

As of 1 January 2021, all ships built after this date and entering ECAs (the Baltic, North Sea and English Channel) must comply to the Tier III standard set by IMO. This standard aims to reduce nitrogen oxide emissions by approximately 85% compared to the Tier II standard which currently applies.

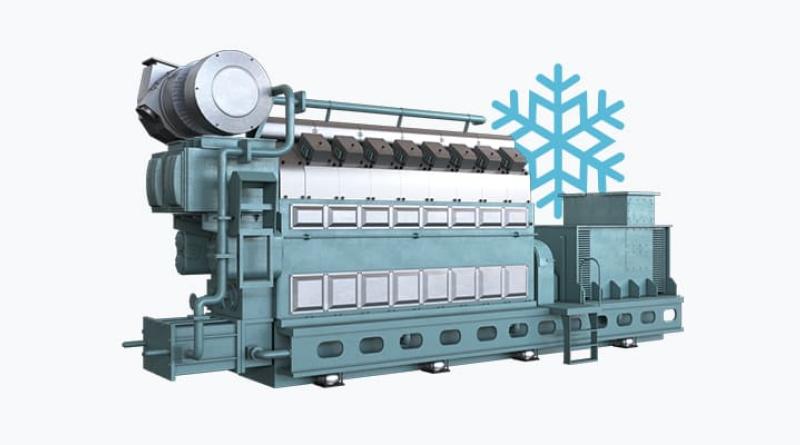

LNG as a marine fuel has gained positive momentum as the global shipping industry looks to adapt to stricter emissions standards. Used as a marine fuel, LNG sharply reduces emissions from ships, resulting in a significant improvement in air quality, particularly for communities in coastal areas and port cities. LNG helps to cut:

- Sulfur emissions by 99%,

- Fine particle emissions by 99%,

- Nitrogen oxide emissions by up to 85%,

- Greenhouse gases emissions by up to 23% (Well-to-Wake)

LNG represents an available and competitive solution that contributes to the International Maritime Organization’s (IMO) long-term strategy of reducing greenhouse gas emissions from ships. Traction in developing LNG bunkering infrastructure has consequently expanded with several leading ports and LNG bunker suppliers alike having established key initiatives, and made significant progress in support of these developments. LNG as a marine fuel also lays the foundation for the introduction of greener bioLNG in the future.

Is it sufficient? There is still much work to do to align with the goals of the Paris Agreement as it is estimated by the International Council on Clean Transportation that the emission trajectory for maritime shipping will overshoot a 1.75°C pathway by between 65% and 150%.

When it comes to engine lubrication, one of the key developments happening now is the importance of engine cleanliness – which is essential in this new operating regime. It is one of the reasons why our technical experts are focused on ensuring all our customers use lubricants and monitoring tools that deliver optimal engine performance and engine cleanliness.

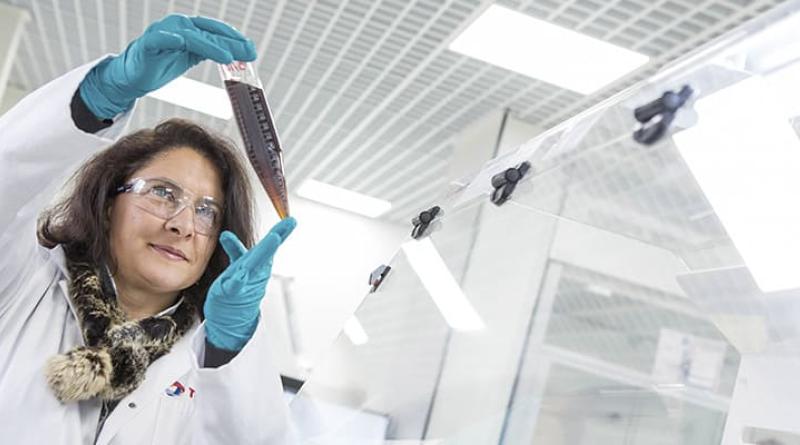

While existing lubricant oils are designed to achieve the reliability of engines running on today’s conventional low sulfur fuel oils, increased research and development into lubricants that will handle alternative fuels of the future is happening at speed – from the ‘here and now’ solution of LNG to the future fuels such as biofuels, synthetic fuels, ammonia, or on mixtures and combinations of these fuels that at the end of the day, aim to match the IMO targets on GHG emissions of vessels running internal combustion engines.

At Lubmarine we continue to strengthen our work with OEMs and the shipping supply chain on how best to develop new formulations of cylinder lubricants and Trunk Piston Engine Oils appropriate to the new fuels of the future, and their application for both 2 stroke and 4 stroke engines. Success has been achieved in qualifying products such as Talusia Universal, which is developed using a unique chemistry that helps the neutralisation process and the control of engine deposit growth in the pistons, rings, and liners. This cylinder lubricant is fully approved by MAN ES for use on all engines operating on <0.50% S VLSFO and with residual fuels containing from 0.5% to 1.5% sulfur. It also bears a DF validation and a NOL by WinGD for use on all engines and all fuels with sulfur content ranging from 0.0% to 1.5%, including LNG.

New fuel and new engine technologies need new types of lubricants. It is one of the reasons why we believe that new chemistries will be the basis for the next generation of engine oils. We have pioneered this strategy with Talusia Optima – a product that uses Ash Free Neutralizing Molecules. This revolutionary lubricant was developed through intensive R&D at our renowned Solaize Research Center.

Looking to the future, the shipping industry will continue to face changes with initiatives that deep dive further in to energy efficiency, emissions and greenhouse gas targets, as industry’s knowledge and experience of new fuels evolve. With engine technology continually evolving, marine lubricant suppliers need to remain agile. At Lubmarine we aim at finding efficient and cost-effective solutions to the challenges ship owners face in the lead up to 2030 and 2050, is more important than ever before in the transition to cleaner shipping for cleaner air.

Learn more on TotalEnergies’ emissions.