Transporting Liquefied Natural Gas (LNG) from the Yamal Peninsula, located deep in the Russian Arctic, is a hugely complex undertaking. Total and its partners have designed a new type of ship: an LNG ice-breaker. This innovative solution allows large shipments of LNG to be transported efficiently and at a steady pace throughout the year and without the assistance of ice-breakers.

The ship, which is 300 metres long and has a capacity of 172,600 m3, can sail in temperatures that fall as low as -52°C and in ice thickness up to 2.1 metres. Between December 2016 and 2019, 15 LNG ice-breakers will be commissioned.

The vessel will be supplied with a range of Total Lubmarine lubes, including main engine oils and auxiliary equipment lubes. Total Lubmarine has a range of lubes suitable for ice-class vessels that are able to cope with temperatures down to -60C.

Classed under the Russian Maritime Register of Shipping, the LNG ice-breaker is graded Arc7, which means that the ship can sail in ice of a thickness of up to 1.7 metres, making it the biggest commercial vessel to hold this certification level. To be able to sail in such conditions, the ship has a strengthened hull and the engine room is protected by a double hull. High strength steel with a yield strength of 500 MPa has been used to reduce the ship’s weight—125,000 tonnes when loaded—and ensure a full load draught of 12 metres.

By opting for a scaled-down ice-breaker bow, instead of a bulbous bow, the ship can sail more easily in open water and in light ice (up to 1.5 m thick). In thicker ice, this double acting ship turns 180° and proceeds astern. The hull’s heavy ice-breaker profile around the stern allows the ship to sail through 2.1 m-thick ice. Numerous tank tests have confirmed the ship’s performance and manoeuvrability on the open sea and in different pack ice conditions.

LNG STORAGE TANKS

The tank containment system installed on the ship is equipped with NO96 GW membrane technology developed by Gaz Transport & Technigaz. Reinforced plywood boxes filled with glass wool provide insulation. With regards to the vibrations associated with operating in ice, glass wool behaves better over time than perlite, which is normally used. The ship is not equipped with a bilge keel, a first for an LNG carrier. This decision was approved after studying the sloshing of LNG in tanks subject to harsh sea conditions.

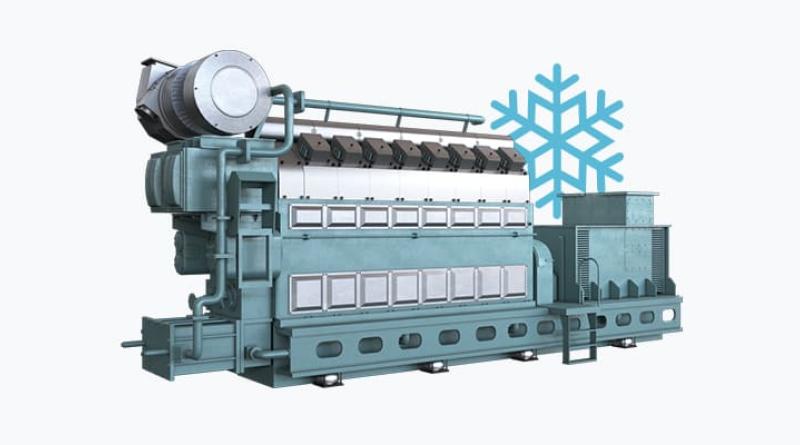

PROPULSION

Propulsion is provided by three ABB Azipod®, units. These azimuth thrusters make the ship easier to manoeuvre in ice. Each Azipod®, contained in a pod under the hull, comprises an electric 15 MW engine that is connected to a propeller; the entire unit can rotate 360° to change the ship’s direction. The Azipod® units allow the ice that is broken by the bow and stern to be crushed and pushed to either side of the ship. Their vorticity causes turbulence that greatly reduces friction between the carrier and the ice. This method is far more effective than the ramming-based approach used by conventional ice-breakers.

THE ENGINE ROOM

The engine room is insulated by a 10 cm layer of fibre glass. The engine room’s ventilation system is not connected to the engine air supply system. The minimum ventilated air temperature is 5°C should the outside temperature fall to -52°C. In order to limit heat loss, almost one third of this air is recycled. The engine cooling system includes a cold water loop that is fed by a seawater chest that acts as an ice/water separator. Some of the warm water produced by this cooling system is directed to the chest to prevent it from getting blocked by ice.

The engine room is divided into two separate areas, partitioned by a firewall. Both areas house the systems that are vital for the ship’s propulsion. This design complies with class notation, AVM-IPS, as certified by Bureau Veritas, and guarantees that the engines remain available in an emergency. In the event of a fire or flooding in one of the two rooms, the carrier can operate on half of its power with two Azipod® units. Tank tests have shown that the ship can continue to sail safely with the assistance of an ice-breaker and reach an open-water harbour where the ship can undergo repairs.

ON DECK

The equipment on the ship’s deck is designed and protected to operate at very low temperatures—down to -52°C. Such winterization, mostly passive, is based on the use of special material, extensive thermal insulation and electric motors, which are more reliable at very low temperatures. Thermal-oil heating systems keep the deck’s strategic areas free from ice and the look-out stations warm. The mooring points are covered to avoid the accumulation of snow and ice and to protect the crew from the cold while manoeuvring.

This LNG carrier has two wheelhouses. The first conventionally points towards the bow and comprises, on the port and starboard sides, two external winterized wings for the monitoring of manoeuvres. The second is located at the rear of the deck and is used when the ship proceeds astern. Both wheelhouses are connected by a walkway which gives this double wheelhouse a T-shaped layout. Each wheelhouse is equipped with all the technology needed to sail in ice: an ice radar, Xenon light, GPS and GLONASS positioning systems, GPS compass, etc.

See www.ep.total.com/en/expertises/liquefied-natural-gas for more detail about Total’s LNG expertise.