We meet Mark Chuang, Total Lubmarine’s technical manager in Taiwan

Reducing complexity is at the top of everyone’s agendas, especially of those Total Lubmarine staff who regularly visit customers and their vessels. Mark Chuang, technical manager, Taiwan has been with Total Lubmarine for over ten years and has completed hundreds of customer and ship visits. He has seen a rapid expansion in activity in Taiwan, China and nearby countries. While the customers that Mark cares for vary in size and the type of operations they perform, reducing complexity is a constant theme to his work.

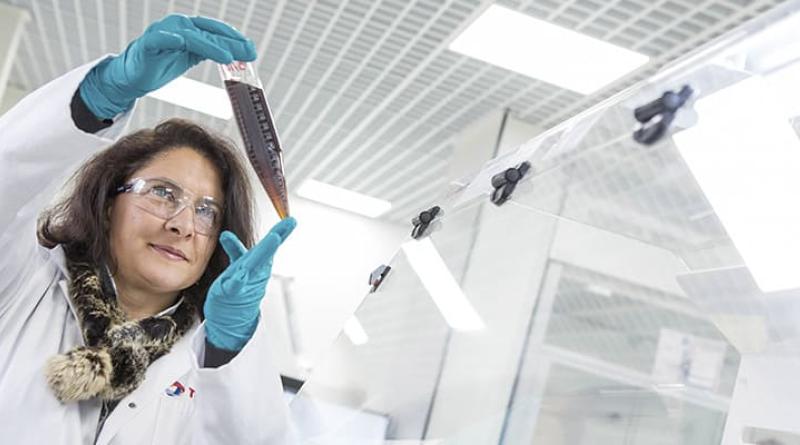

Mark is in daily contact with Total Lubmarine’s technical team in France and engine manufacturers, staying abreast of the latest technical and regulatory issues. On a weekly and sometimes daily basis, he collates all relevant information to be relayed to customers and simplifies technical advice into practical steps to be actioned by ship owners and managers or by a ship’s crew directly.

At customer seminars, Mark guides and coordinates information sharing with company managers while maintaining regular contact with ships’ crews through ship visits. From fleet managers to third engineers, it is important to ensure that employees at all levels are fully up to date with engine lubrication issues and are fully aware of the solutions that Total Lubmarine is able to provide.

Engine lubrication in Emission Control Areas (ECAs) generates many questions from customers who are keen to formulate a strategy to power and lubricate their engines cost effectively whilst using the correct fuel and lube combinations.

Explaining the effect of new regulation, Mark said:

“Since 1 January 2015 ships have been required to burn fuel with a sulphur content of less than 0.1% in emission control areas (ECAs). To begin with, many customers were unsure of how best to manage the lubrication of their engines when switching between high and low sulphur fuels several times during the same voyage. Working with customers, we were able to create strategic lubrication plans using new products from our range including LS25 and Talusia 100 as well as monitoring tools and then implementing them through our network.

Having consolidated these plans with several months’ experience of operating in ECA zones with the 0.1% sulphur content fuel requirement, customers and engine manufacturers alike are interested in the long term effect of new operating patterns on their engines. As we are in the privileged position of having equal access to OEMs and ship owners, we are playing an important intermediary role. Ultimately we can bring cutting edge technical know-how to customers, including advice for new-buildings.”

To achieve optimum solutions, Mark meets with company management alongside Total Lubmarine’s area sales manager, combining commercial offers with sound technical advice. Crucially, Mark will visit vessels to inspect engines and lubricant storage tanks and devise a lubrication strategy that ideally requires a vessel to carry no more than two lubricants at once. This avoids confusion on the part of the crew and puts ship owners and managers’ minds at rest.

If a vessel has insufficient tank storage capacity, Total Lubmarine supplies barrels for the duration of a voyage, delivering via its strong network that can deliver to over a thousand ports worldwide.

While Mark is able to fulfill customers’ needs and find solutions for all engine issues with the current Total Lubmarine range, he is pleased that the company is working on the next generation of single marine cylinder oil, and looks forward to reducing complexity even more.