The COVID-19 pandemic has affected the cruise industry in unthinkable ways, which has forced some owners and operators in this sector to consider placing vessels in layup. The idea of a layup is to preserve the ship’s structure and integrity of its components and equipment by protecting against corrosion and machinery wear and tear. But it’s not as simple as you might think.

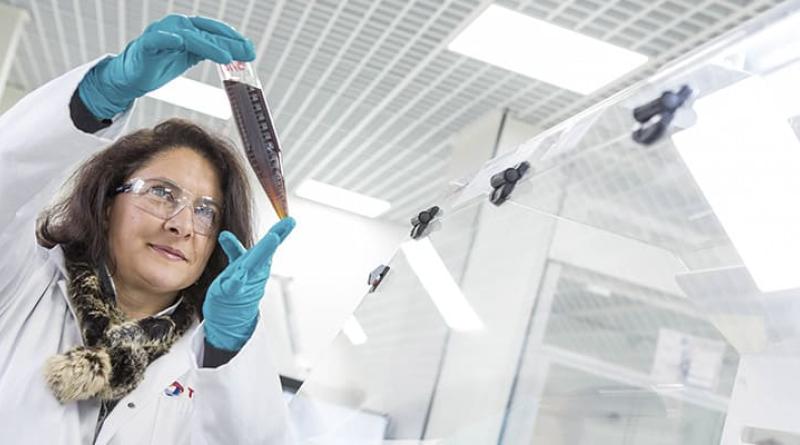

In the recently published interview with International Cruise Ship International, Serge Dal Farra, Global Marketing Manager at Total Lubmarine, shares his insight.

We always recommend that any layup should follow the requirements of the OEMs and the guidance provided by Class societies. We recommend that during a period of static mooring, engines and auxiliary equipment are kept fully inspected and lubricated even in stand-by mode. You want that part of the process to be as smooth and risk-free as possible.

And, irrespective of the nature and the magnitude of the anticipated changes in the industry, we can safely assume that lubricants will continue to play a pivotal role in supporting the complete energy production chain. Simply getting things done is key for our customers’ piece of mind. That’s why we are working to alleviate the current pressure across the cruise sector and use the down time to further reinforce and back up the supply chain, so when travel restrictions are fully lifted, cruise lines can get back to business and focus on their core activity without worrying about lubricant supply and stocks.

Discover more on Serge’s insight in this latest interview that can be downloaded here.

Learn more on our solutions for cruise ship industry.

*****

Read more articles on cruise industry: