Lubmarine’s Global Brand Manager Cécile Joannin recently spoke at the Propulsion and Future Fuels Conference in Hamburg, highlighting the role that marine lubrication will play in supporting the shipping industry’s decarbonization transition targets towards 2030 and 2050.

Here she shares how lubricant manufacturers like Lubmarine are supporting, and will continue to support, the shipping industry – through a combination of innovative solutions.

Working towards 2030 and beyond

As we head towards 2030 and the initial IMO landmark of 20% GHG emissions reductions, it is clear that shipping’s decarbonization journey is gathering pace. The IMO’s revised and strengthened emissions targets strategy, which was set out in 2023, has set the bar at 70% emissions reductions by 2040 (compared to 2008) and zero carbon emissions by 2050, sharpening the focus still further.

Challenges for lubrication manufacturers

According to classification society DNV, it has logged 268 new orders for alternative fuel vessels to date in 2023, including 112 LNG-powered and 152 methanol-powered ships(1).

June and July saw the most activity related to LNG with 47 new orders combined, whereas July propelled methanol-powered vessels across the 200 ships mark with 48 new orders.

But new fuelled vessels are only part of the transition challenge. The ripple effect from the IMO targets runs throughout every aspect of the global marine fuels supply chain, from fuel developers, producers and suppliers through to storage and delivery infrastructure, equipment manufacturers and of course lubricant manufacturers.

The future basket of marine fuel solutions represents multiple challenges from a lubricant development and manufacturing perspective. Some of those challenges facing lubricant manufacturers include:

- Gaining greater expertise and knowledge on new fuels combustion performance data (kinetics, emissions, heat rejection)

- Determining and neutralizing the impacts of new fuels combustion on oil performance and ageing

- Evaluating the performance of different lubricant formulations

- Field testing – finding candidates and setting up supply

- Industrializing and establishing global supply

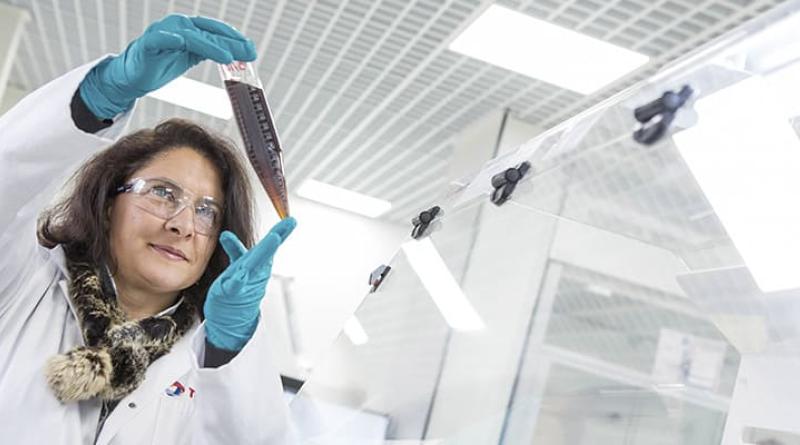

As a result, our R&D and technical teams are focussed on the different fuels in the mix and the potentially different performance requirements they have, looking to answer the formulation puzzles around key issues such as:

Finished product stability - Compatibility - Oxydation stability - Hydrolysis

Detergency - Dispersancy - Thermal stability - Corrosion - Wear protection