Whilst the spotlight within the maritime industry is increasingly focussed on the multiple future fuel pathways that will power the shipping industry towards its decarbonization targets towards 2050, there is also the reality that currently over 99% of the world’s shipping fleet is using conventional fuels (1).

According to the IMO’s recently launched website developed by the Future Fuels and Technology Project (FFT Project) - utilizing the latest data from the DNV’s Alternative Fuels Insight Platform (AFI) – just 0.83% of the world’s shipping fleet is currently using alternative fuels including LNG and LPG.

Whilst this picture is changing, with approximately 16% of new vessels on order having alternative fuel capability including LNG, Methanol, LPG, Hydrogen and Ammonia(1) the majority of the world’s shipping fleet will likely be using the current conventional fuels including LNG well into the 2040s, given an expected vessel life span of between 20 and 30 years.

This points to the fact that future demand for conventional and LNG fuels will be significant for some time to come, which will be reflected in demand for marine lubricants that meet the operational parameters of these engines into the foreseeable future.

Dr Olivier Denizart, Lubmarine’s Technical Manager looks at the continual work that is being done by Lubmarine to develop new and improved marine engine lubricants to meet today’s – and tomorrow’s – global shipping fleet.

--------------------------------------------------------

Today, lubricant manufacturers like ourselves are simultaneously working on developing improved lubricants for existing mature fuel solutions (conventional and LNG fuels), whilst developing new lubricants to meet the needs of future fuels including Bio fuels, e-fuels, MeOH and NH3.

That’s because the primary drivers for lubricants are ever-changing in line with engine designers and manufacturers who are striving for further performance improvements that can help deliver increased fuel economy and emissions reductions in today’s engines. The result is that new engine designs are placing increased demands on lubricants and their performance capabilities in a range of ways including:

- Increased temperatures and pressures in the engine

- Exhaust Gas Recirculation

- Exhaust After Treatment

As a result, we are seeking to deliver further performance improvements to today’s lubricants looking at areas including:

- Detergency

- Thermal stability

- Oxidation resistance

New Engine Designs and Cylinder Oil Specifications

Demands placed on cylinder lubricants by today’s engines mean that we must pay special attention to the key areas of the combustion chamber, the ring pack, the exhaust valve and especially the piston top land and top ring area.

For this we are focusing on low ash – for deposit control, and high detergency - for cleanliness.

We also need to look at key Operational Drivers including:

- Fuel efficiency

- Emissions control

- Lower carbon footprint

- Better reliability

Importance of ring groove cleanliness

The importance of good piston ring cleanliness cannot be overstated. This has been seen through the more recent MAN Category II introduced to the market.

Not just about lubricant performance

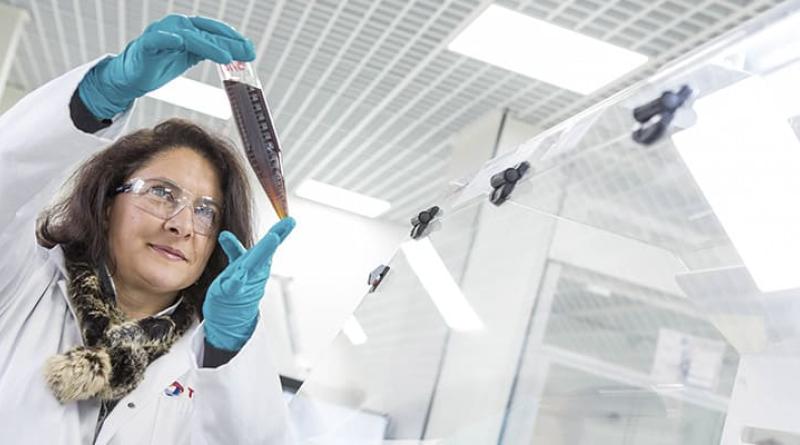

In addition to the need for improved lubricant performance, new HSE regulations could limit the use of some traditionally used chemical components in marine lubricants, creating the need for new components and formulations to be identified, tested and utilised within marine lubricants - something our R&D teams are continuously working on. With this technology, we can develop new lubricant formulations that improve energy efficiency and the cleanliness of today’s marine engines operating on conventional fuels, whilst contributing to reduced emissions.

Developing new lubricants with a range of performance benefits

One example of the work we have done through our research centre is the development of an experimental and ground-breaking new 4-stroke ‘fuel economy lubricant’ that has already yielded significant fuel savings during yearlong sea trials.

The new fuel economy lubricant – planned for engine maker approvals in 2025 - has been derived following significant research and development at TotalEnergies. The result is innovative lubrication performance that reduces engine friction, and in doing so reduces fuel consumption by up to 4% - depending on operating conditions.

The benefits to the user beyond engine lubrication performance includes significant cost savings and energy efficiency for 4-stroke vessel operators, particularly across the Cruise, Ferry, Off-Shore and Powerplant sectors.

This is a real breakthrough and innovation in 4-Stroke Trunk Piston Engine Oils. Through this new lubricant we can now have a positive impact on fuel economy, and therefore CO2 emissions, which will ultimately support the move towards future IMO regulations on GHG emissions.

Conclusion

Tomorrow’s multiple fuel solutions will undoubtedly be built on the learning and development that is taking place in today’s shipping market – including the effective lubrication of marine engines.

There will not be a future moment when there is a universal switch over to new fuels and new engines, rather a transition through sustained evolution. In the case of Lubmarine that means the continual development of innovative lubrication solutions which deliver effective engine lubrication performance today, building towards tomorrow.

References:

(1) Future Fuels IMO