A year and 3 months in to IMO 2020 and we are already seeing how the transition is shaping a cleaner industry. New internal combustion engines (ICEs) that are readily available across the shipping industry are being designed to match the targets on GHG emissions from the international shipping sector according to the IMO goals:

- reduce carbon intensity of 40% by 2030, and of 70% by 2050

- reduce GHG emissions of 50% by 2050

But what about the current engines operating in today’s ocean-going vessels? Lubrication is needed to ensure their smooth and efficient performance. Advancements in the chemistry of lubes ensures engines can run cleaner and are optimized for better performance. However, any adaptation of an engine lubricant is influenced by two parameters both of which are aimed at minimizing emissions and to reduce fuel consumption:

- the increase of the constraints in engine operation, e.g. increase of peak pressure, increase of temperature, and the recirculation of exhaust gases.

- the diversity of the fuels available at the point of purchase, existing or renewables, and the way to use them in marine engines.

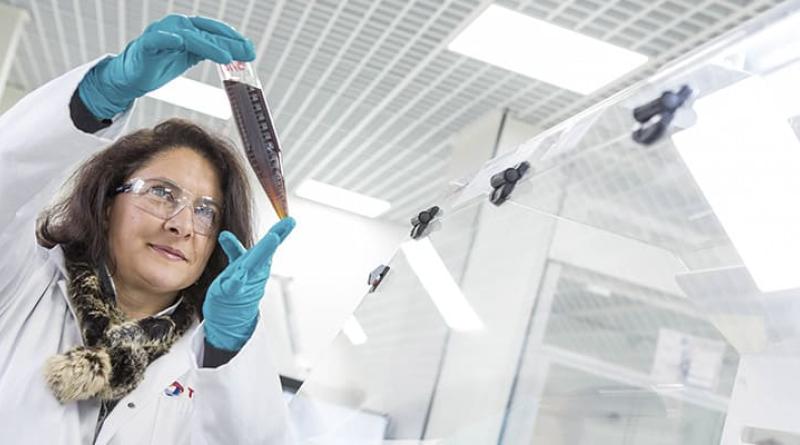

As Jean-Philippe Roman, Project Manager at Lubmarine, explains to Clean Shipping International, Lubmarine experts are always focused on identifying performance issues relating to the fuel and lubricants used by each ship operator in their engines.

“We assess their chemical nature and base assessments on the engine operating condition reported by the engine manufacturer, and we work closely with the OEMs on all elements of lubricant development and options by sharing insight and knowledge on our product chemistry, engine inspections and recommendations. Our product chemists address performance issues through the formulation and chemistry of the lubricant.”

The article emphasises how the energy major is ahead of the curve with its recently requalified TALUSIA UNIVERSAL single cylinder oil, and how the business is leading technically advanced engine lubrication solutions and services that are helping optimize engines of the future.

“This process is complex because the lubricant has a critical role to play in achieving engine cleanliness in all conditions,” highlights Jean-Philippe. “Our approach applies to any engine design (with any OEM) and to any engine technology (diesel or dual-fuel) – engine lubricants must handle the potential issues related to each fuel mix available to the operator, and they must also provide a level of qualification in the reliability of the emission treatment systems that are coupled to the engine.”

To achieve the planned goals of 2030 and beyond, Jean-Philippe suggests we all have a responsibility to work in cooperation with various stakeholders in a project. “The collective mindset of all the lubricant manufacturers including our own, is set on the ambition to develop viable technologies and to test it at scale. As an industry, we must also look to change our paradigm and thinking. Lubricants are not just for a unique fuel type – the conventional fuel oils of the market – but for engines of various technologies, flexible enough to run on many different fuel types, from the ‘here and now’ solution of LNG to the future fuels such as biofuels, synthetic fuels, ammonia, or on mixtures and combinations of these fuels that at the end of the day, aim to match the IMO targets on GHG emissions of vessels running internal combustion engines. TALUSIA UNIVERSAL is an example of this where we have created a single cylinder oil for multiple fuel use, including LNG.”

You can read Jean-Philippe’s insight in the latest edition of Clean Energy Shipping (pages 42-43).