How is digital transformation changing, and is set to change, the shipping industry? Olivier Suming, Service Product Manager of Total Lubmarine, provides his view on the areas ripe for Industry 4.0 investment.

Industry 4.0 is soon to be the ‘new norm’ driven by data and characterised by the ‘Internet of Things’ (IoT), Cyber Physical Systems and Cloud Computing.

This digital transformation is proving a challenging journey for many organisations, as they move to create efficiencies and reduce costs by converting traditionally manual time-consuming tasks into digital processes - and in the longer term seek to harness the potential of computer analytics, such as artificial intelligence, and create meaningful insight from data sources.

As with any new digital application, however, it is important that the strengths and limitations of the technology and its approach are fully understood in order to truly provide a level of reassurance, transparency and value for money.

The COVID-19 pandemic has itself been a ‘forced’ test bed for the use of digital tools and software, as part of the solution to practise social distancing while maintaining an efficient commercial operation. And, while there continues to be a vast scope for more technology-based applications in the near-future, I can see value in how digitisation can further enhance today’s operations.

The maritime sector, and shipping in particular, is one of the growing optimised industries, and with abundant opportunities for improvements through data and digital transformation. Areas ripe for a new wave of innovation include fuel efficiency, engine monitoring and efficiency, ship to shore data exchange, real-time logistics, automation and environmental impact.

Last year’s report by Allianz in its Shipping and Safety Review highlighted an assessment of 26,022 shipping incidents and identified that the safe operation of a ship is dependent on the reliability of the ship’s main propulsion engine. Reliability of the main propulsion engine is interdependent on the reliability of several subsystems including lubricating oil system, fuel oil system, cooling water system and air system. Failure of any component or element can lead to serious and costly consequences for an engine. We see huge value in the role digitisation and technology can make in helping to provide a level of foresight to ship operators and their engineers to improve and better support decision making around predictive maintenance and efficient engine performance. One example is how sensors on engines can collect vital data in real time providing timely recommendations on maintenance and inspection.

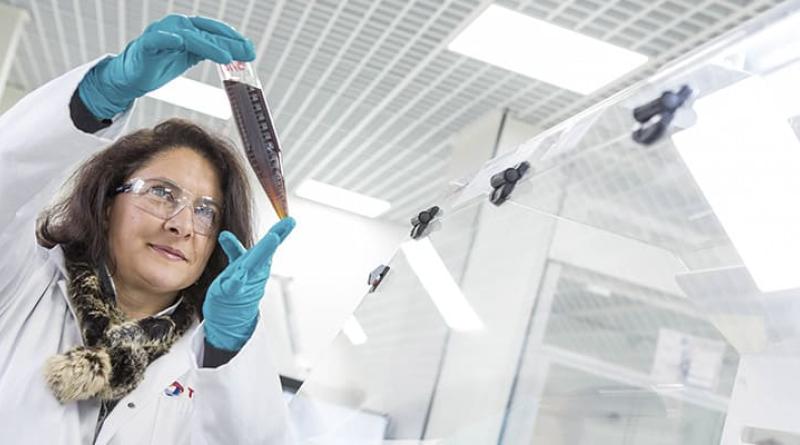

Technologies powered by vast flows of data are transforming linear supply chains into digitally interconnected networks with entirely new opportunities. At the heart of this evolution is how to drive customer value across our networks as we see benefit in the use of data and digitalization to support our customers in reducing the environmental impact of their activity.